What is a packaging upgrade?

It is the systematic analysis and improvement of existing packaging, not just about simply replacing materials,Instead, it starts with environmental compliance、Cost optimization、Structural safety、The four dimensions of brand image are optimized as a whole。

Environmental compliance | Cost optimization | Structural safety | Brand image

Applicable scenarios

- The original packaging materials do not meet the export environmental protection standards (such as plywood is difficult to recycle)

- The packaging structure leads to inefficient transportation、High cost

- The internal cushioning material is highly polluted、Not easily degradable (pearl cotton、plastic, etc.)

- Customers want to enhance brand value through packaging image

Service process

- Packaging analysis (dismantling existing packaging.),Assess pain points)

- Upgrade Scheme Design (Structural/Material/Process Improvement)

- Cost calculation (compare data before and after renovation)

- Sample Making & Testing (Strength、Resistant to breakage、Transport simulation)

- Customer confirmation and mass production

- Continuous optimization after upgrade

Our usual upgrade scheme

Wooden case→ heavy duty corrugated box + wooden pallet

- Reduces total weight,Save on shipping costs

- Meet European and American environmental protection laws

- The intensity of transportation is not reduced

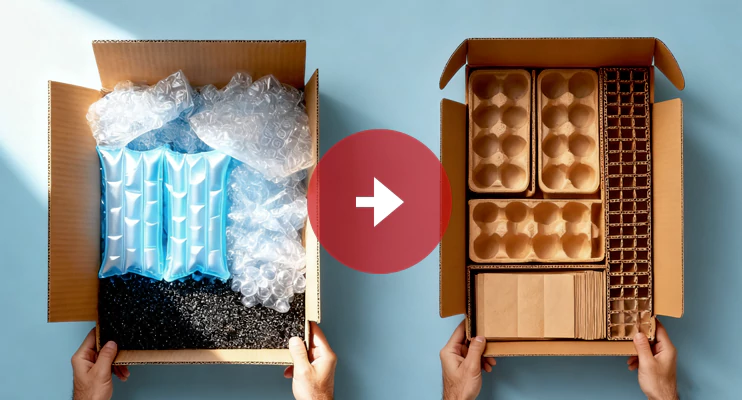

Pearl cotton/foam → paper structure cushioning

- Honeycomb board、Concave square tube support

- Green and recyclable,Reduce plastic use

Structural optimization→ cost reduction and efficiency increase

- Adjust the size and arrangement,Improve the loading rate

- Reduce material waste

Appearance upgrade → brand enhancement

- High quality printing、Custom colors

- Improve the user unboxing experience

Core strengths

Full category replacement capability

Not only in paper packaging,Wooden pallets are also available、metal parts and other combinations

Environmental compliance

Familiar with national regulations,Ensure the first pass of the exit inspection

Cost reduction and data

Use data to compare costs and efficiency before and after transformation

Multi-industry experience

New energy、machine、home appliances and other mature cases

Typical customer cases

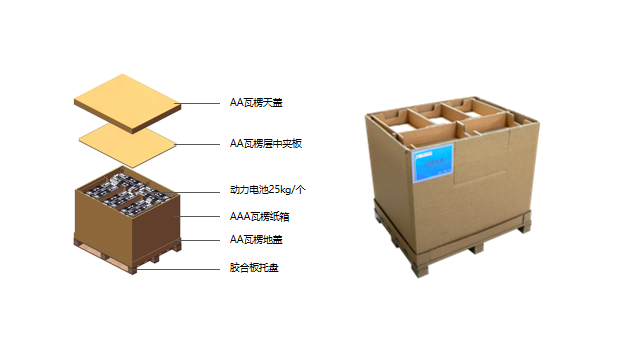

Power battery packaging upgrade plan

Original plan

- Individual corrugated carton single package

- The battery per case is about 25kg

- Loading and unloading are cumbersome、High shipping costs、Insufficient stacking strength

Upgrade plan

- Wooden pallet + AAA heavy-duty corrugated boxes

Interior heavy vaneker design - 35 batteries in a single case (5×7 layers)

- 1.2M*1m standard pallet design,Maximize export container loading rate

- Dynamic load-bearing:900medical history,Stack 2 layers

- 20% reduction in costs

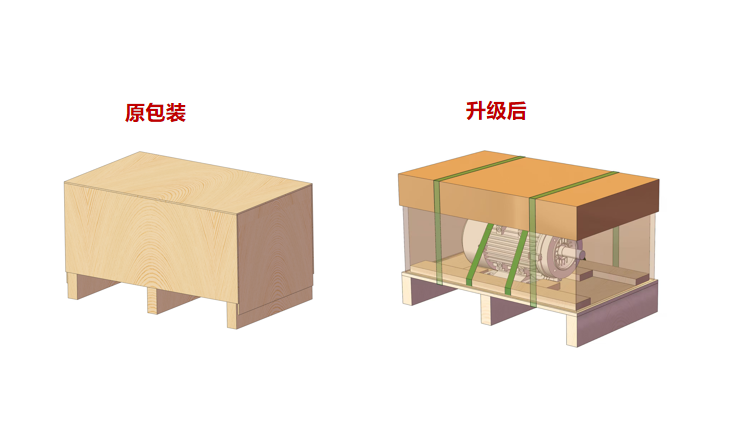

Servo motor wooden box to carton solution

Original plan:

- Wooden pallet + wooden box

- A single servo motor weighs about 70kg

- Export transportation and stacking requirements are high,The cost is high

Upgrade plan:

- Changed to wooden pallets + AAA heavy-duty corrugated boxes

- Remove the wooden frame,Only replace with heavy corrugated carton outer frame

- A single box can be stacked in 5 layers,No additional support material is required

- The material is environmentally friendly and recyclable,30% reduction in costs

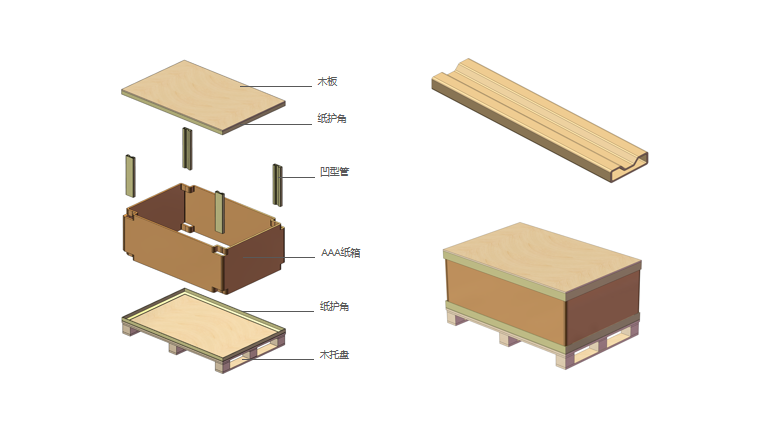

Fushan wood to paper plan

For larger and heavier devices:Fushan patented concave tube structure can be added,The overall load-bearing can be reached 1.5– 2 tons

For high stack layers、Scenarios where transportation distances are long:A wooden board can be added to the top layer to balance the load-bearing

Paper corner guards can be added on all sides,Further enhance stability and compressive performance

Win-win cooperation,Start with communication

-

Safely stack full and empty boxes

Safely stack full and empty boxes

-

Closed container,Ensure safe transportation

Closed container,Ensure safe transportation

-

Water and dust resistant

Water and dust resistant

-

100%recyclable

100%recyclable